In thousands of homes on well water, acidic water causes thinning of copper pipes, pinhole leaks, and numerous copper

pipe leaks over time. Acidic water filtration systems can easily correct and neutralize a low pH in well water.

The pH scale is a scale from 1 to 14. A neutral pH is 7. A ph of less than 7 is considered acidic. A pH greater than 7 is considered alkaline and is less corrosive to copper pipes than waters with a pH of less than 7.

Signs of acid water are corrosion of fixtures, blue staining (from copper pipes) or rust staining (from iron pipes). Acidic water can also cause pinhole leaks and pipe failure over time. By raising the pH to the range of 7.0 to 7.5 the water can be made alkaline which will then reduce or eliminate pipe corrosion.

Common causes for acidic water are acid rainfall due to atmospheric carbon dioxide and other airborne pollutants, runoff from mining spoils, and decomposition of plant materials. Acidic waters can be of good quality and are typically low in buffering calcium minerals, but are high in dissolved carbon-dioxide gas, which can cause the low pH or acidity.

An acidic water filtration system is also known as a calcite neutralizer filter. One of the most convenient methods to raise pH, and add a little hardness and alkalinity is to use a calcite neutralizer filter. These filters will typically raise the pH of the water to 7.0 to 8.0 and add 30 to 100 ppm of hardness depending on the alkalinity and water hardness. The water will taste better and in most applications no water softener will be required after the calcite neutralizer filter.

In neutralizer filters, the acidic water slowly dissolves the calcium and magnesium media on contact as the water flows through the filter, raising the pH of the water and increasing the alkalinity. This eliminates the effects of corrosive water chemistries and can help to prevent corrosion of piping and fixtures.

The size of the system is directly proportional to the flow rate of the water, in gallons or liters per minute. The higher the flow rate, and the more gallons per minute flows through the pipes, the larger the system required. Generally for most homes with 1 bathroom, a 1 cubic foot size system containing 100 lbs of calcite will work well. For homes with 1 to 2 bathrooms, a 1.5 cubic foot filter is recommended. For higher flow demands and in homes with 3 to 4 bathrooms and larger families, a 2.5 cubic foot neutralizer containing 250 lbs of calcite is recommended.

Neutralizer filter tanks contain a small amount of filter gravel in the bottom of the tank and are filled to two-thirds full with a blend of calcium and magnesium carbonates made from naturally occurring minerals. These minerals dissolve into the water, making it less corrosive. More mineral can quickly and easily be added to the filter tank, typically once per year for most residential applications. No special tools are required.

The neutralizer filter should be installed after the pressure tank but before any copper piping in the house. If the pressure tank, check valve and pressure switch are installed with copper piping the copper piping should be replaced with PVC or stainless steel pipes up to the inlet of neutralizer filter. It is OK to have copper pipes installed on the outlet of neutralizer filter since the water is neutralized at this point and the pipe will be protected.

This type of neutralizer also acts as a filter removing sediment and small amounts of rust from the water, and then backwashing it out once every week or so. The most common type of acid neutralizer filter has an automatic backwash control valve. The frequency and length of the backwash cycle can be easily adjusted on the control valve. Most backwashing acid neutralizer filters are set to backwash once a week for eight to ten minutes. This backwashing cleans the calcite filter media and allows the mineral media to more easily dissolve into the water over time.

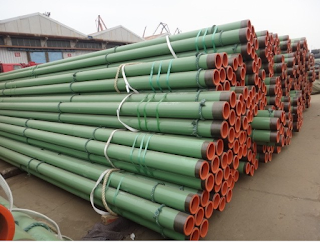

Various steel

pipe external coating projects are currently implemented by our company including single-layer/ double layer FEB, 2PE, 3PE, 3PP and other anti-corrosion coatings with the performed standards such as DIN 30670, DIN 30671, DIN 30678, CAN/CSA-Z245.21-M92, SY-/T4013-2002,SY/T0315-97 etc.