HDPE or High-density polyethylene is made with petroleum, which is also known as polythene when it is used for manufacturing water pipes. It is highly appealing for its wide strength-to-density ratio and its higher resistance against different solvents. This material is used in the production of water pipes, which are used to supply water in a building as a municipal water system part. Furthermore, with its brilliant quality features, this HDPE material is also ideal to manufacture geomambranes, plastic bottles and plastic lumber etc. In addition, pipes made from HDPE material have resistance to acid and alkaline and are available with high flow characteristics. Therefore, according to their sizes and specifications, a pipe is provided with different range of pressure rating. Basically, size of a pipe ranges from 20 to 1600 mm and these products are available with long working life such as more than 50 years in a normal condition.

Pipes in different sizes are applicable in sprinkler, drip irrigation, bore well, water supply, lift irrigation, cable ducting, sewerage/drainage, pesticide dispersal etc. In addition, they are also useful in flow applications, chemical/processing industries, dairies and other liquid and semi-liquid conveyance etc. Water is supplied in a smooth and continuous manner due to their effective and smooth inner surface. Moreover, HDPE pipe suppliers offer a hygienic range of pipes with UV resistance and easy installation at any place. All of their products are made from materials that do not have composition of heavy metal additives. These products provide pollution free flow of portable water to the consumers without any electrochemical corrosion.

With features like high ductility, non-toxic nature, smooth yet rigid construction and fine finish, the pipes are designed with a facility to easy transport them anywhere as they are light in weight and have good flexibility. Other quality characteristics of these products include resistance to abrasion, twisting, earthquake and impact, low friction coefficient and improved capability. Both types of welding that is electro fusion welding and butt welding are applied on this product in order to provide rigid joints in a reliable manner. In addition, HDPE sockets or couplers both are useful to join these pipes mechanically to provide excellent performance.

Suppliers offer pipes with pressure ratings mentions as PN 2.5-4-6-8-10-12.5 and 16 with reduced holding and installation costs. Provided with low notch sensitivity, they supply all of their products easy handling and transportation features at very affordable prices. Moreover, they source all of their products from certified and trusted vendors with no any compromise with product quality. Therefore, some of the suppliers also provide installation facility for the customers in order to help them in installation. There are so many pipe suppliers are available across worldwide.

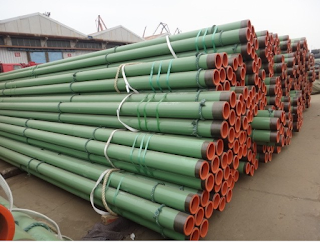

Various steel pipe external coating projects are currently implemented by our company including single-layer/ double layer FEB, 2PE, 3PE, 3PP and other anti-corrosion coatings with the performed standards such as DIN 30670, DIN 30671, DIN 30678, CAN/CSA-Z245.21-M92, SY-/T4013-2002,SY/T0315-97 etc.

|

| Anti-corrosion Pipes |

没有评论:

发表评论