Plumbing pipes corrode over time. And neglecting to address this issue until a clog or rupture occurs will cost you a lot. Corroded pipes that burst or backup is an extremely messy, tedious, and invasive repair project. The results can force a person or family out of their home for quite some time, influence tenants to break leases, and even pose health hazards. For this reason, proper and routine plumbing care is necessary to avoid pipe damage and health problems, as well as, to protect your home's structural integrity. One innovative and effective method to preventing pipe corrosion and subsequent problems is epoxy pipe lining. Continue reading to learn more about epoxy pipe lining, how it works, and how it can benefit your home for years to come.

Plumbing Pipe Repair

Epoxy Pipe Lining Pipe repair, also referred to as "re-piping" in the plumbing industry, is not a quick and simple process. In fact, it requires the skills of a true licensed master plumber, not just a standard or contract plumber. These plumbers are fully-certified to manage the most complex and dangerous plumbing services, designs, and repairs. Re-piping is invasive, and simple replaces old piping materials with new ones; new ones that will only need to be replaced over and over again. It requires a long stint of work, time, money, and mess, and doesn't always fix the underlying problem. Fortunately, there is an alternative to re-piping called epoxy pipe lining.

Not only is it efficient and less-evasive, it is cost-effective as well. Rather than starting demolition on location, digging holes and drilling into underground piping, epoxy pipe lining simply uses existing entrance points to access the plumbing pipes that need repaired. This saves a substantial amount of time, labor costs, money, and mess. The epoxy pipe lining inner coating material is safe and non-toxic, keeping drinking water contaminant-free and safe to use for all applications. It inhibits sewage from entering local water systems as well. A master plumber can explain all the details to pipe re-lining and repair in regards to your particular and unique plumbing system.

|

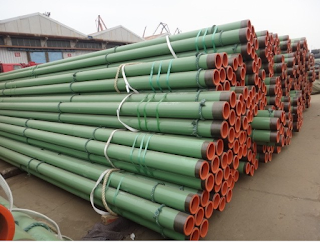

| Anti-corrosion Pipes |